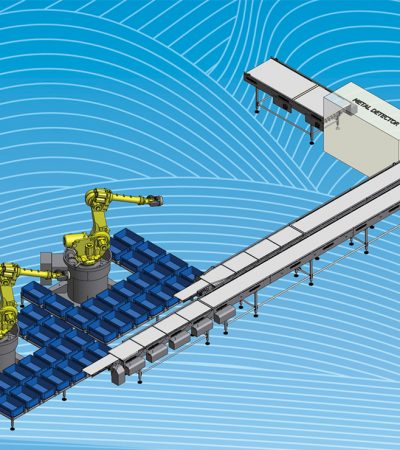

This short list of highly technological solutions includes also the robotized sorter for production departments for the handling of portioned meat and semi-processed products. It is a modular and extremely flexible system that, thanks to the jointly use of two anthropomorphous robots, can distribute different cuts arriving from the processing lines at a group of matrix-organized crates. For some applications, it is also possible to put in a certain group of crates all the meat parts deriving from the same quarter in such a way as to keep trace of the animal of origin.This solution is applied in many different industrial realities, also in sectors greatly differing from the one originally thought, above all within distribution logistics.

Pulsar Industry engineers and manufactures the mechanics, control boards, equipment and automation of the whole system, and last but not least, software control of department production. This specific function is operated by Dynamic, the departmental software for production control in the food industry, for overall management, simple and efficient batch traceability, accurate and highly automated quality files management. Entirely designable by the user, they can be easily organized and connected with the most significant event of the production process In addition to this, Dynamic can also read and compare all function data in such a way as to provide graphics of the variances, from efficiency and productivity parameters in real time. Using Dynamic, the already Pulsar Industry’s customers are able to line out the improvements areas of their plants thanks to the OEE index. This is the first, crucial step to increase marginality.