On occasion of trade fair IFFA 2022 Pulsar Industry presents some innovative solutions for production and packaging departments, among which the bag and tray robotized automatic cartoning system for cold cuts and cubes respectively, stands out.

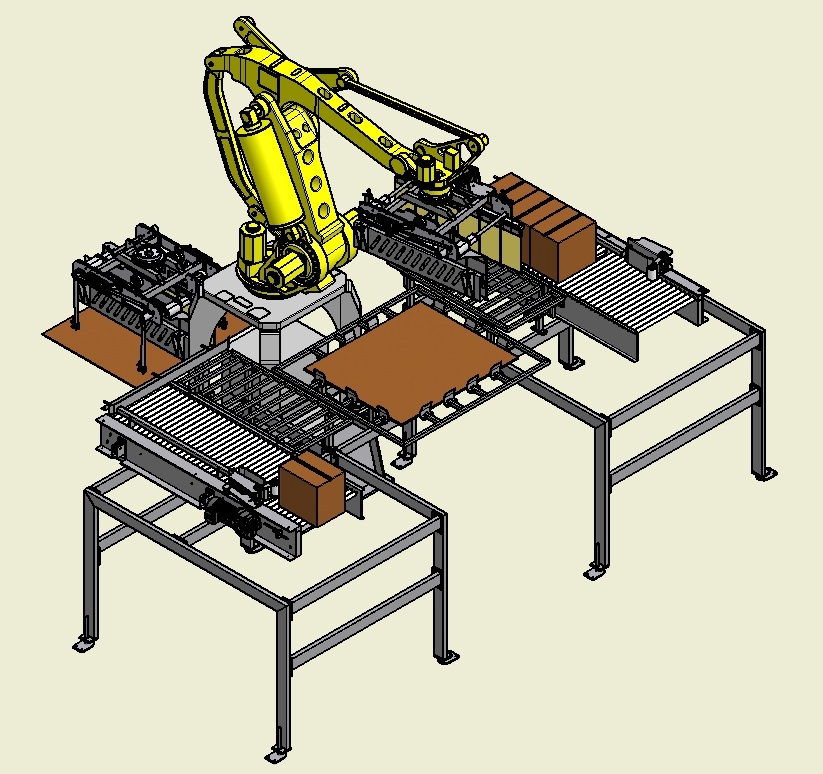

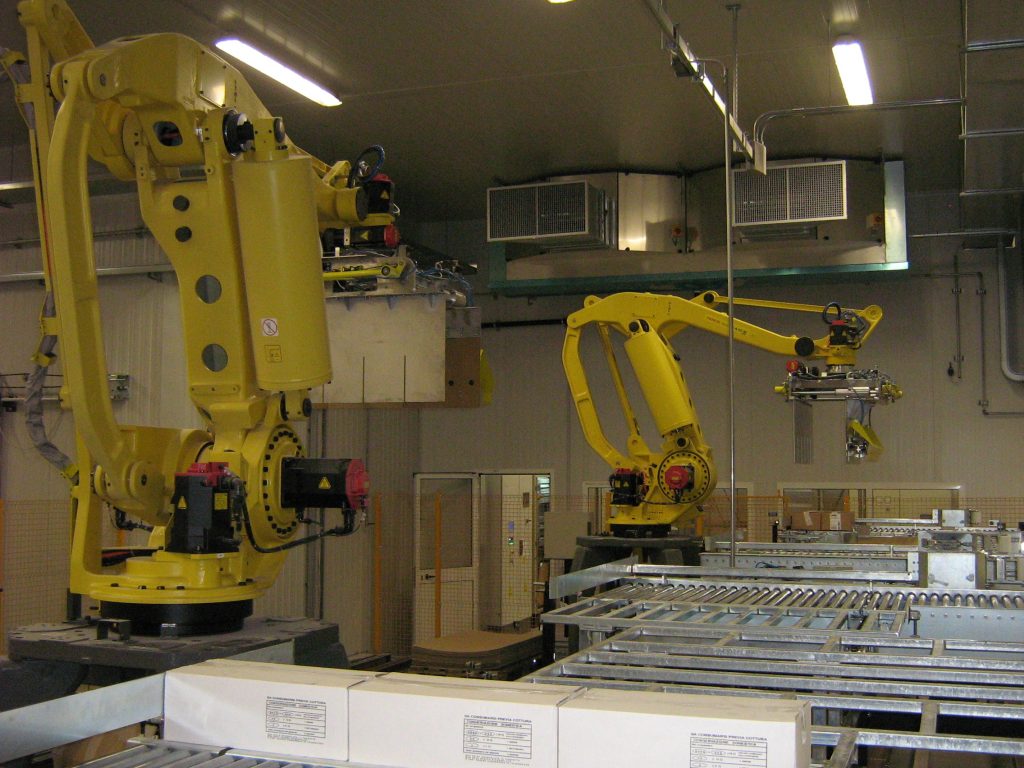

This is a highly compact monobloc housing one or two parallel kinematic robots, depending on the packaging process requirements. Supported by a vision system of the latest generation, the robots detect the product coming from the production lines, in single or multiple tray, pick and orient it correctly, lay it smoothly inside the final container. Once completed, the cartons are conveyed to the following sections of the line to be closed and labelled.

For bag packaging in the same monobloc, we can find a parallel kinematic robot to form piles of the required size, and a small anthropomorphous robot to pick the piles of bags for the following insertion into previously pre-formed carton, with any angle. Any kind of carton can be filled by these systems, also the one to be displayed to the public.

The system proposed by Pulsar Industry features high flexibility, high performance and complete modularity, and it enables to equip the packaging departments of also the most demanding customers, thus enabling considerable resource saving and exceptionally quick return of investments.

Pulsar Industry engineers and manufactures the mechanics, control boards, equipment and automation of the whole system, and last but not least, software control of department production.

This specific function is operated by the department al software Dynamic for production control in the food industry, for overall management, simple and efficient batch traceability, accurate and highly automated quality files management. Entirely designable by the user, they can be easily organized and connected with the most significant event of the production process.

In addition to this, Dynamic can also read and compare all function data in such a way as to provide graphics of the variances, from efficiency and productivity parameters in real time. Using Dynamic the already Pulsar Industry’s customers are able to line out the improvements areas of their plants thanks to the OEE index. This is the first, crucial step to increase marginality.