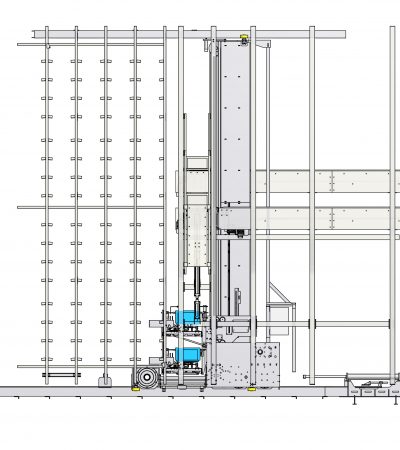

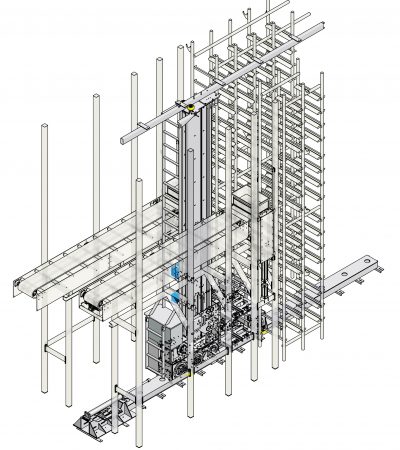

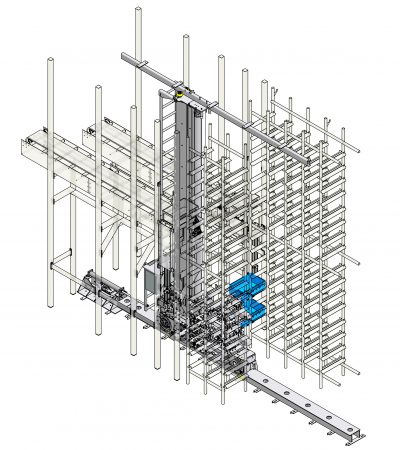

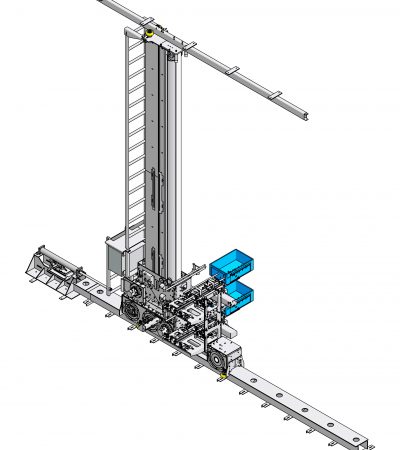

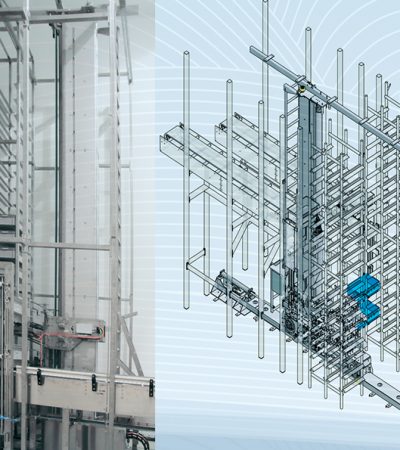

The automatic stainless steel warehouses is one of the most recent Pulsar Industry’s realizations. Designed to store and handle crates for fresh meat or semi-processed products, it can also be built upon customer’s requirements, of different heights and depths. The travelling lift fully made in stainless steel can also be equipped with multiple picking arms thus maximizing the capacity of the system in every mission. The whole plant is also provided with an automatic sanification system that intervenes also in the most hidden places without the man to intervene.

Pulsar Industry engineers and manufactures the mechanics, control boards, equipment and automation of the whole system, and last but not least, software control of department production. This specific function is operated by Dynamic, the departmental software for production control in the food industry, for overall management, simple and efficient batch traceability, accurate and highly automated quality files management. Entirely designable by the user, they can be easily organized and connected with the most significant event of the production process In addition to this, Dynamic can also read and compare all function data in such a way as to provide graphics of the variances, from efficiency and productivity parameters in real time. Using Dynamic, the already Pulsar Industry’s customers are able to line out the improvements areas of their plants thanks to the OEE index. This is the first, crucial step to increase marginality.